Cast,

not welded!

Our innovative manufacturing process gives our hollow rotors

high levels of strength. This means longer run times,

less down-time and, therefore, lowers costs for our customers.

Engineered

in Germany

Each of our models is developed in Oberschwaben

for our special method.

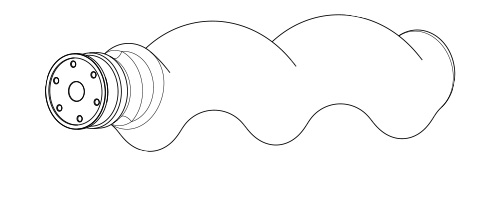

Hollow rotor

Neuentwicklung von Rotoren für Exzenterpumpen nach dem Prinzip der Drehverdrängung.

What we have developed

In light of the increasing requirements regarding service life and the growing demand for better performance in the area of progressive cavity pumps, we have, for technical and ecological reasons, developed a technology that allows us to use a casting method to manufacture the rotors of the pumps as hollow rotors.

Hollow rotor

Compared to conventional rotors, the weight can be reduced by up to 70%. This lighter weight of the rotors makes them significantly easier to handle, e.g. during their installation into the stator, which can be performed by a single person without the use of auxiliary equipment.

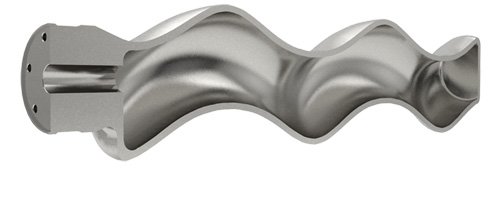

Casting method

The clear advantage compared to hollow rotors manufactured by means of welding is the homogeneity of the material achieved through the use of the casting method,

which practically eliminates the risk of breaks in the rotor.

2.5 Meter - Our currently longest rotor

Cast blanks: 2.5 m / nominal diameter x,

in comparison one of our standard rotors with 1.4 m / nominal diameter x

2.5 m rotor after machining

- Innovative manufacturing system

- Rotor is comprised of a single piece,

enabling use of high-alloy tooling steels (also high-grade steels). - Compared to welded rotors,

significantly better mechanical features are achieved - Yield strength > 630 N/mm

- Tensile strength 900 – 1,200N/mm2

- Tempering 62 HRC 0.5-1.0 mm penetration depth

- The use of higher-quality materials increases the service life

- Homogeneous distribution of the material in the rotor leads to a significantly lower risk of breaking

- Special surface coating with HVOF/HVAF

- Further developments:

- Long rotors with hollow construction

- Hollow rotors with internal cooling

- Multi-spiral hollow rotors

Advantages

"My hollow rotor and stator

for a BSA barrel with a sliding shoe distributor

(pump BSA HD 150 /110 ) was delivered shortly after

we had ordered it. We installed it with no

problems whatsoever and were able to continue working

with the slurry barrel immediately."

Heinz Morgenegg, farmer from Öhningen

Engineered

in Germany

Each of our models is developed in Oberschwaben

for our special method.

Contact

We are looking forward to receiving your requests.

Pumpentechnik Oberschwaben

phone ++49 (0) 7545 / 911-747

fax ++49 (0) 7545 / 911-785

mobil ++49 (0) 152 / 2216 4694

email: info@pt-ob.de